Equipment as Testimony:From Material to Measurement

At Liaoyuan, our commitment to quality is underpinned by an in-house inspection capability that ranks among the most comprehensive in the industry. While many competitors rely on third-party testing, we invest in advanced technology to monitor and validate every critical stage under one roof. This direct control ensures the highest standards of performance and reliability while guaranteeing faster turnaround and absolute data integrity for our clients.

Group 1: Material Foundation Certification

This suite of equipment validates the very essence of our raw materials—their chemical composition and fundamental mechanical properties.

-

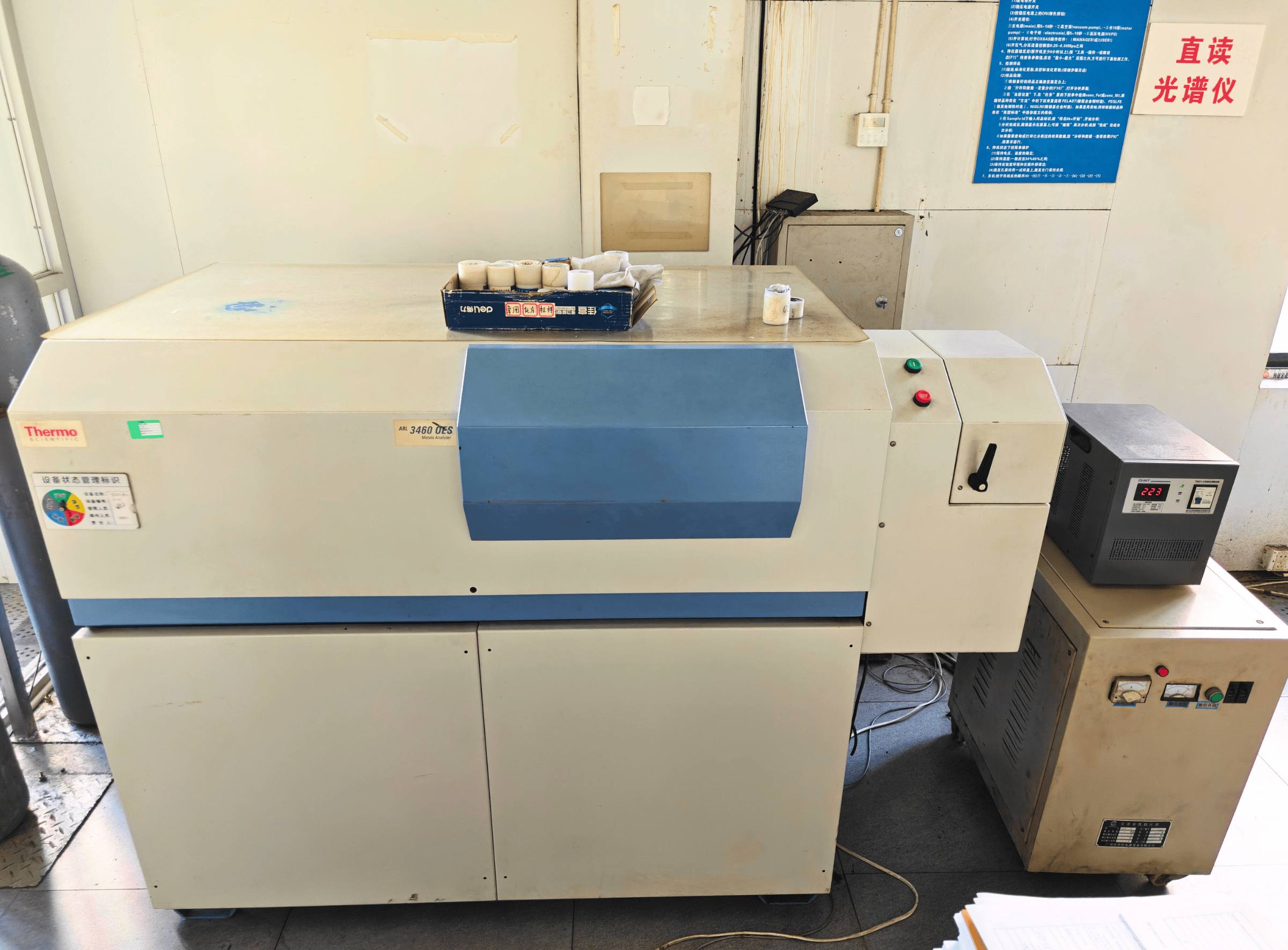

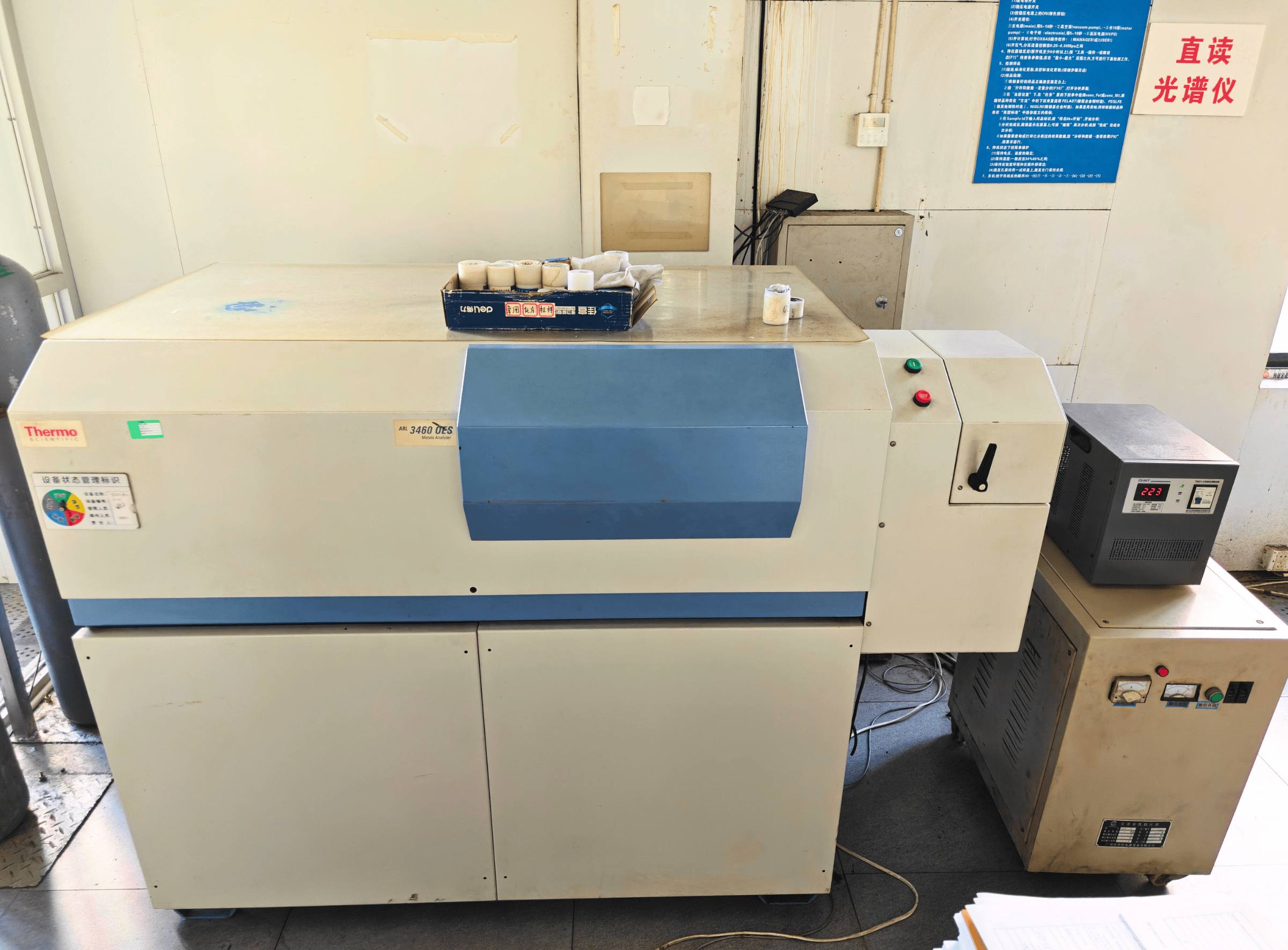

OLYMPUS XRF Spectrometer

Determines the chemical composition of materials to ensure the correct grade of alloy steel and other metals are used. OLYMPUS XRF Spectrometer

OLYMPUS XRF Spectrometer -

Universal Testing Machine

Measures key mechanical properties including tensile strength, yield strength, and elongation through tensile, compression, and bend tests. -

Impact Testing Machine

Evaluates material toughness (impact energy) under high-velocity impact, crucial for assessing performance in low-temperature or harsh environments. -

Automatic Jominy Testing Machine

Conducts Jominy end-quench tests, the standard method for determining steel hardenability, critical for developing effective heat treatment processes.

Group 2: Internal Integrity Verification – From Macro to Micro

We employ a range of non-destructive testing (NDT) technologies to ensure structural integrity by detecting internal imperfections without damaging the component.

-

Ultrasonic Flaw Detector

Uses high-frequency sound waves to detect internal defects such as inclusions, porosity, and cracks. -

OLYMPUS PAUT (Phased Array Ultrasonic Testing) Device

Employs advanced Phased Array Ultrasonic Technology for precise, rapid imaging and sizing of complex internal flaws. OLYMPUS PAUT Device

OLYMPUS PAUT Device -

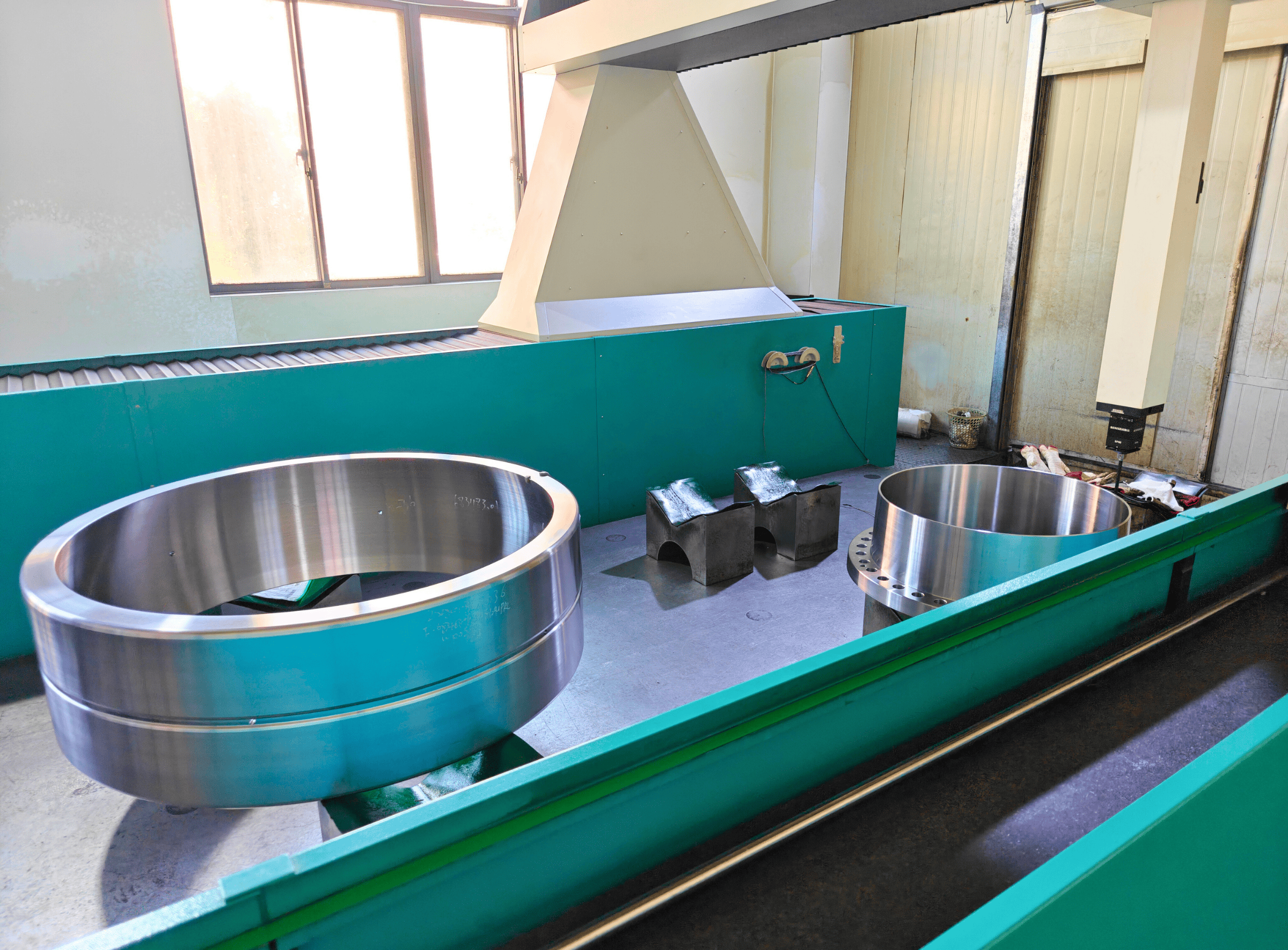

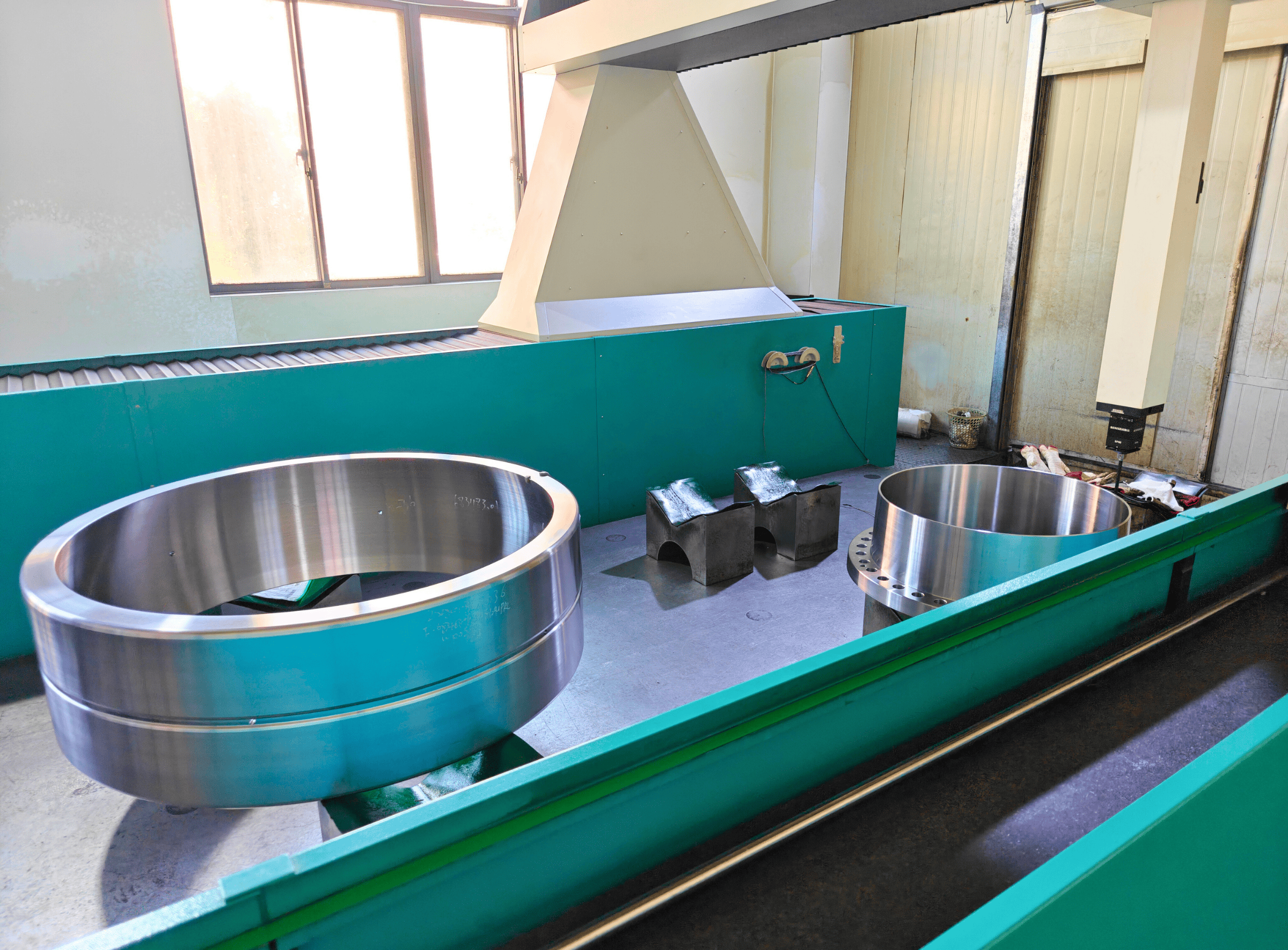

KARL DEUTSCH Immersion UT Scanner

Provides superior coupling stability for high-precision, automated inspections—ideal for critical components like bearing rings and mill rolls.

KARL DEUTSCH Immersion UT Scanner

KARL DEUTSCH Immersion UT Scanner

-

OLYMPUS Metallographic Microscope

Reveals material microstructure (e.g., martensite, bainite, grain size), essential for verifying heat treatment quality and supporting R&D.

Group 3:Surface & Microscopic Insight

This group focuses on detecting surface-level defects and analyzing material microstructure, providing insight into our manufacturing quality.

-

Magnetic Particle Inspection (MT) Equipment

Detects surface and near-surface cracks in ferromagnetic materials like steel and iron. -

Magnetic Particle Inspection

Magnetic Particle Inspection

Group 4: Precision Dimensional & Geometric Verification

Post-machining, we verify that every dimension, form, and positional tolerance meets the exacting specifications of the design.

-

Wenzel CMM (Coordinate Measuring Machine)

The ultimate authority for precise measurement of complex 3D geometries and geometric tolerances on machined parts.  Wenzel CMM

Wenzel CMM

-

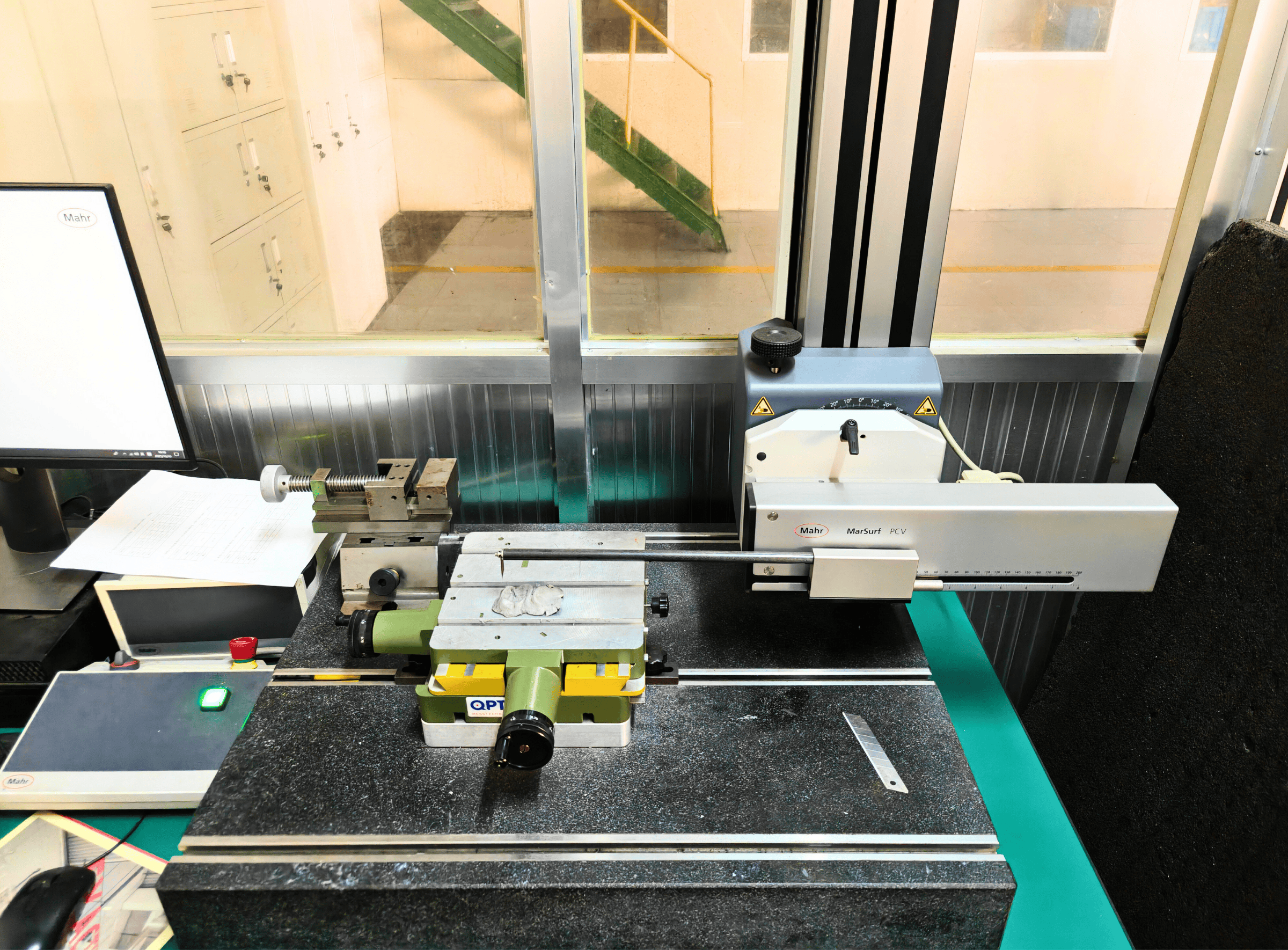

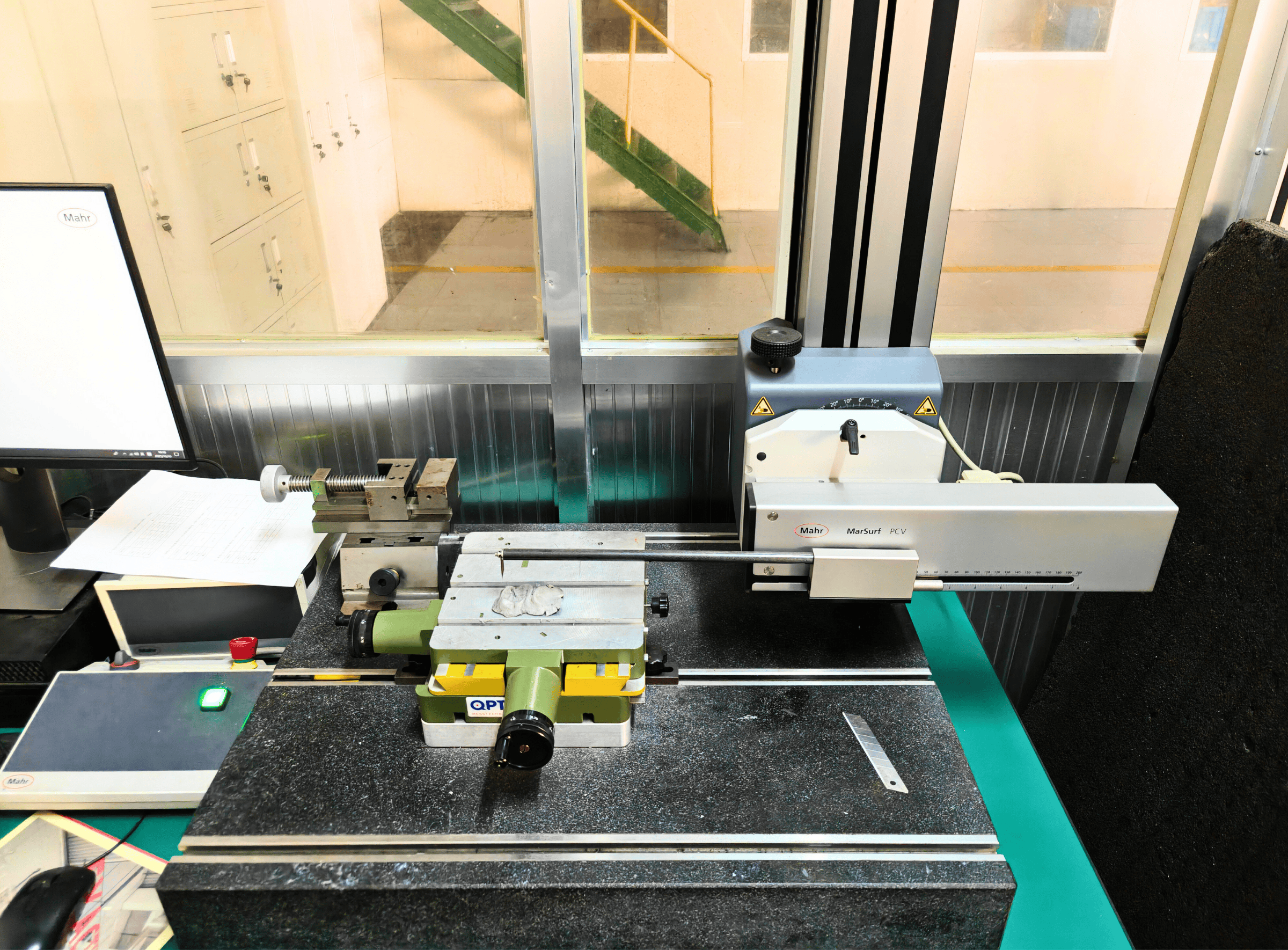

Mahr Contour and Roughness Profiler

Measures contour shape and surface roughness of workpiece surfaces for precision surface finish verification.

Mahr Contour and Roughness Profiler

Mahr Contour and Roughness Profiler

Group 5: Process Monitoring & Specialized Testing

We monitor critical process parameters in real-time and conduct product-specific performance validation to ensure consistent production quality.

-

Portable Infrared Thermometer

Provides remote, non-contact monitoring of real-time workpiece temperature during forging and heat treatment, ensuring process accuracy. -

Rockwell & Leeb Hardness Testers

Measure material hardness to verify heat treatment results. Rockwell for high-accuracy lab use; Leeb for portable, rapid testing on large components.

Group 6: Design Validation & Proof Testing

-

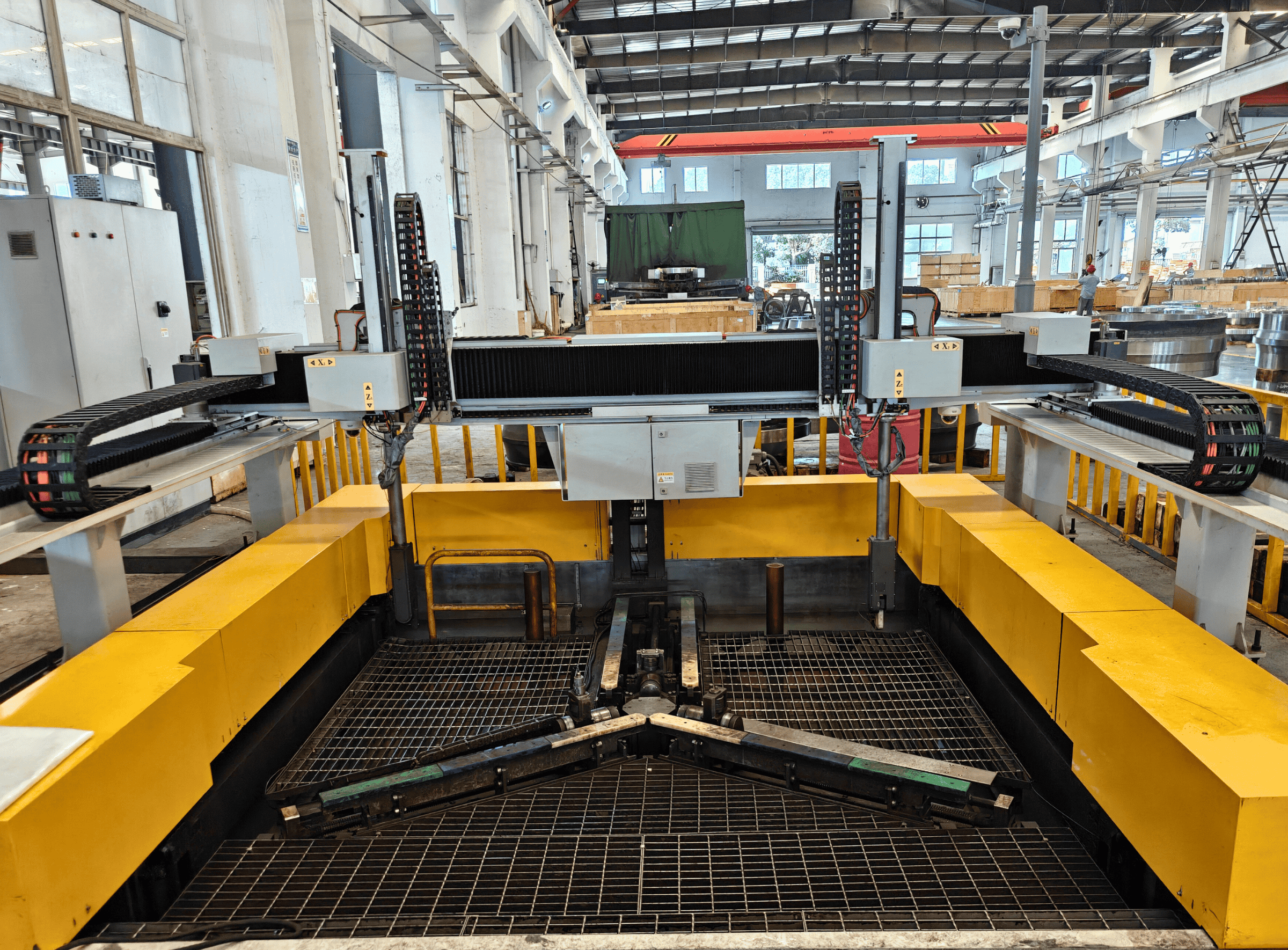

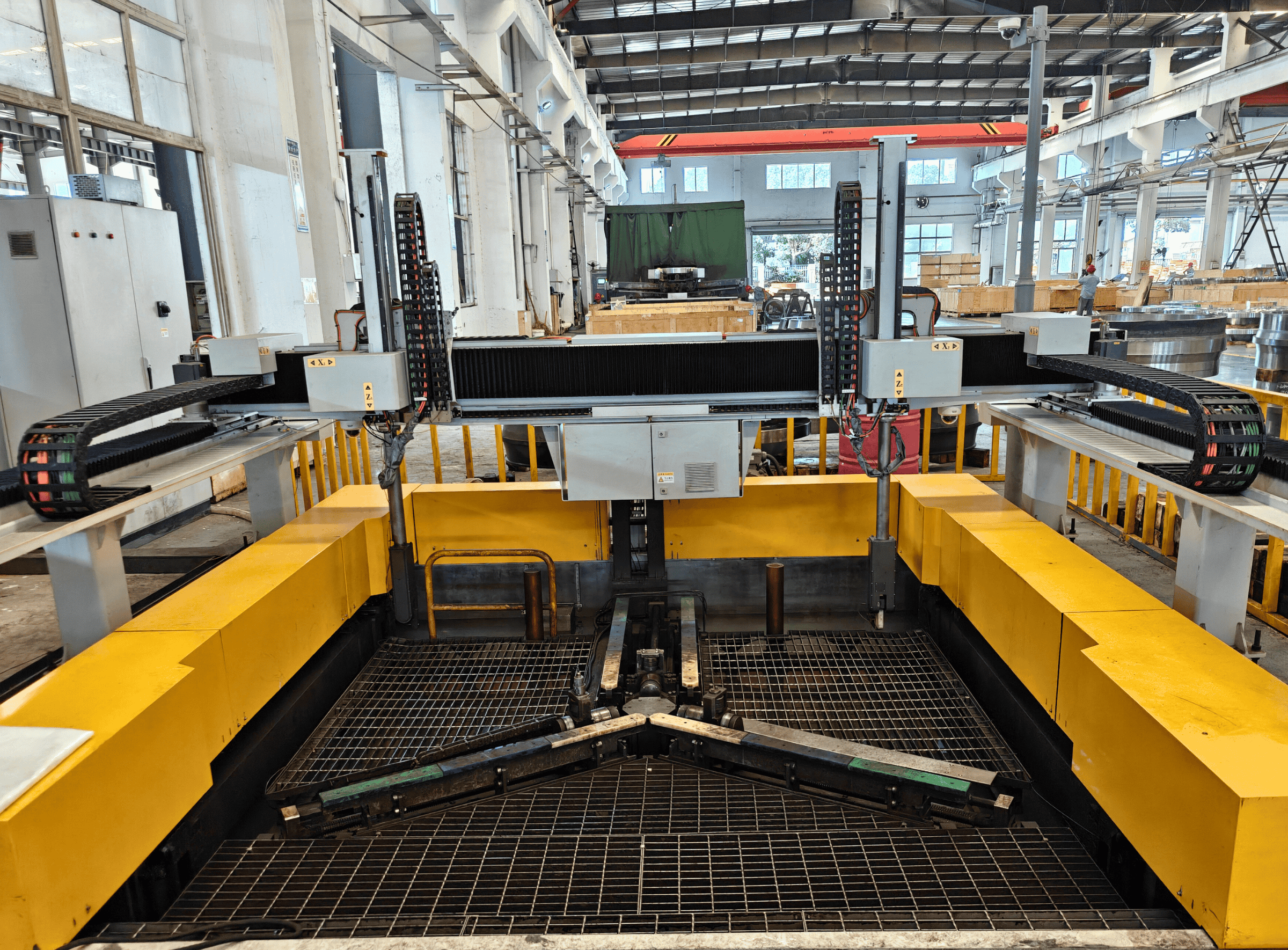

20,000 kNm Shrink Disc Torque Testing Machine

This purpose-built, rare asset is where our designs meet their ultimate proof. It performs destructive testing to validate the maximum torque transmission capacity and torsional strength of our shrink discs, generating certified performance data that provides unparalleled confidence in your design choices and sets us apart from the competition.

The Liaoyuan Advantage: Your Assurance of Superior Quality

Choosing Liaoyuan means more than just accessing advanced equipment; it means partnering with a team that holds its quality evidence to a higher standard. Our extensive in-house capabilities, which exceed typical market offerings, translate into tangible benefits for our customers:

- Reduced Risk: Comprehensive testing from raw material to finished part minimizes the chance of field failure.

- Faster Time-to-Market: Integrated testing eliminates the delays of third-party labs.

- Data You Can Trust: Direct control over the entire testing process ensures the integrity and traceability of every report.

This is not just Quality Control; it is Quality Assurance — built on evidence and engineered for your peace of mind.

Learn how we ensure every forging meets our standards through a clear product identification and traceability process.

OLYMPUS XRF Spectrometer

OLYMPUS XRF Spectrometer OLYMPUS PAUT Device

OLYMPUS PAUT Device KARL DEUTSCH Immersion UT Scanner

KARL DEUTSCH Immersion UT Scanner Magnetic Particle Inspection

Magnetic Particle Inspection  Wenzel CMM

Wenzel CMM Mahr Contour and Roughness Profiler

Mahr Contour and Roughness Profiler