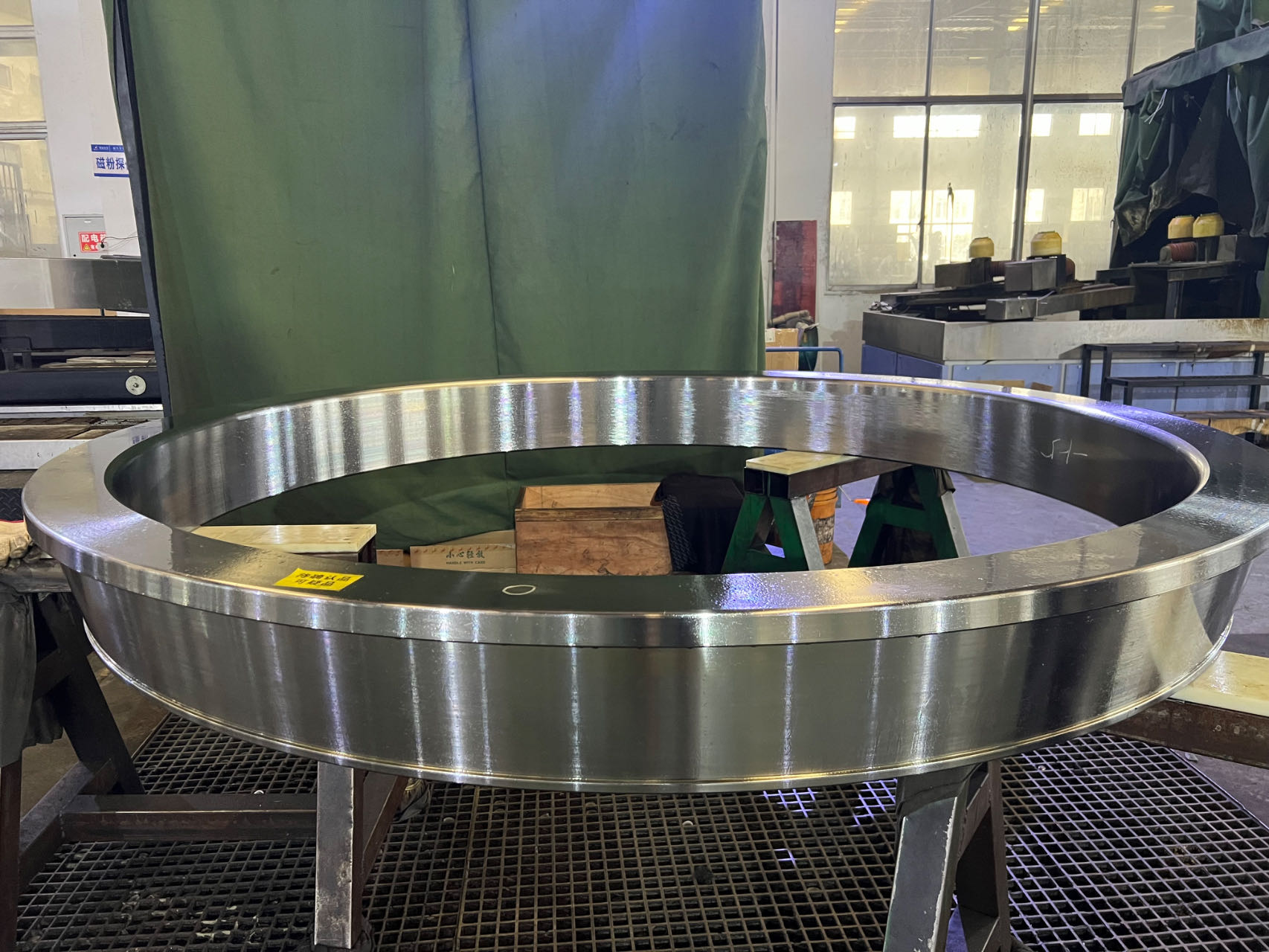

The TRB (Tapered Roller Bearing) ring is a precision ring-rolled component engineered to withstand combined axial and radial loads. A complete tapered roller bearing assembly consists of an inner ring, outer ring, rolling elements, and a cage. In wind turbine applications, TRB

Bearing Rings play a crucial role in transmitting torque within the drivetrain—from the gearbox or rotor to the generator. Through optimized structural design, these rings improve torsional rigidity and operational stability, reduce deformation under heavy loads, and ensure long-term reliability of

Wind Power systems.

Manufacturing Process & Quality Control We follow a strict manufacturing and quality inspection process to guarantee the integrity and performance of every bearing ring:

1, Incoming Material Inspection

2, Blank Cutting

4, Post-Forging Inspection

5, Normalizing + Annealing

7, Mechanical & Chemical Testing

8, Rough Turning

9, Semi-Finish Turning

10, Comprehensive Inspection:

- Dimensional Check

- Ultrasonic Testing (UT)

- Magnetic Particle Testing (MT)

- Spectrochemical Analysis

- Traceability Marking

11, Cleaning | Packing | Storage

Material: High-carbon alloy bearing steel (e.g., 42CrMo4, 34CrNiMo6)

Industry Applications - Wind Power Equipment – Main shaft wind turbine bearing rings for MW-class wind turbines, supporting the core transmission system.

- Heavy-Duty Machinery & Construction Equipment – Mining machines (continuous miners, tunnel borers), excavators, compactors, rolling mills, large conveyors, etc., where high combined loads exist.

- Industrial Power Transmission Systems – Large gearboxes, pumps, compressors, and high-reliability heavy-load applications.

- Energy & Power Generation Equipment – Hydropower turbines, thermal power units, and auxiliary systems in nuclear power plants.

Key Advantages -

High Strength & Fatigue Resistance – Ring rolling combined with heat treatment delivers excellent torsional strength and long fatigue life, supporting continuous high-load operation in wind turbines.

-

Precision Fit & Low Vibration – Tight dimensional control ensures perfect alignment with mating Transmission Components, reducing vibration and noise.

-

Wide Specification Range – Net weight from 100 kg to 6 tons, with minimum diameter ≥ 100 mm, covering multiple wind turbine power levels.

-

Reliable Material Performance – Made from premium high-carbon alloy bearing steel, offering a balanced combination of toughness, durability, and extended service life after heat treatment.

This combination of ring rolling, precision machining, and controlled heat treatment makes TRB rings ideal for high-reliability core components in modern wind turbine drivetrains.Our Tapered Roller Bearing Ring TRB Ring provide a reliable foundation for Wind Power Equipment and Heavy-Duty Machinery. To complete your drivetrain, consider our

Alloy Steel First-Stage Planet Pin Shafts, which deliver superior strength, durability, and dimensional accuracy for optimal performance.