Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

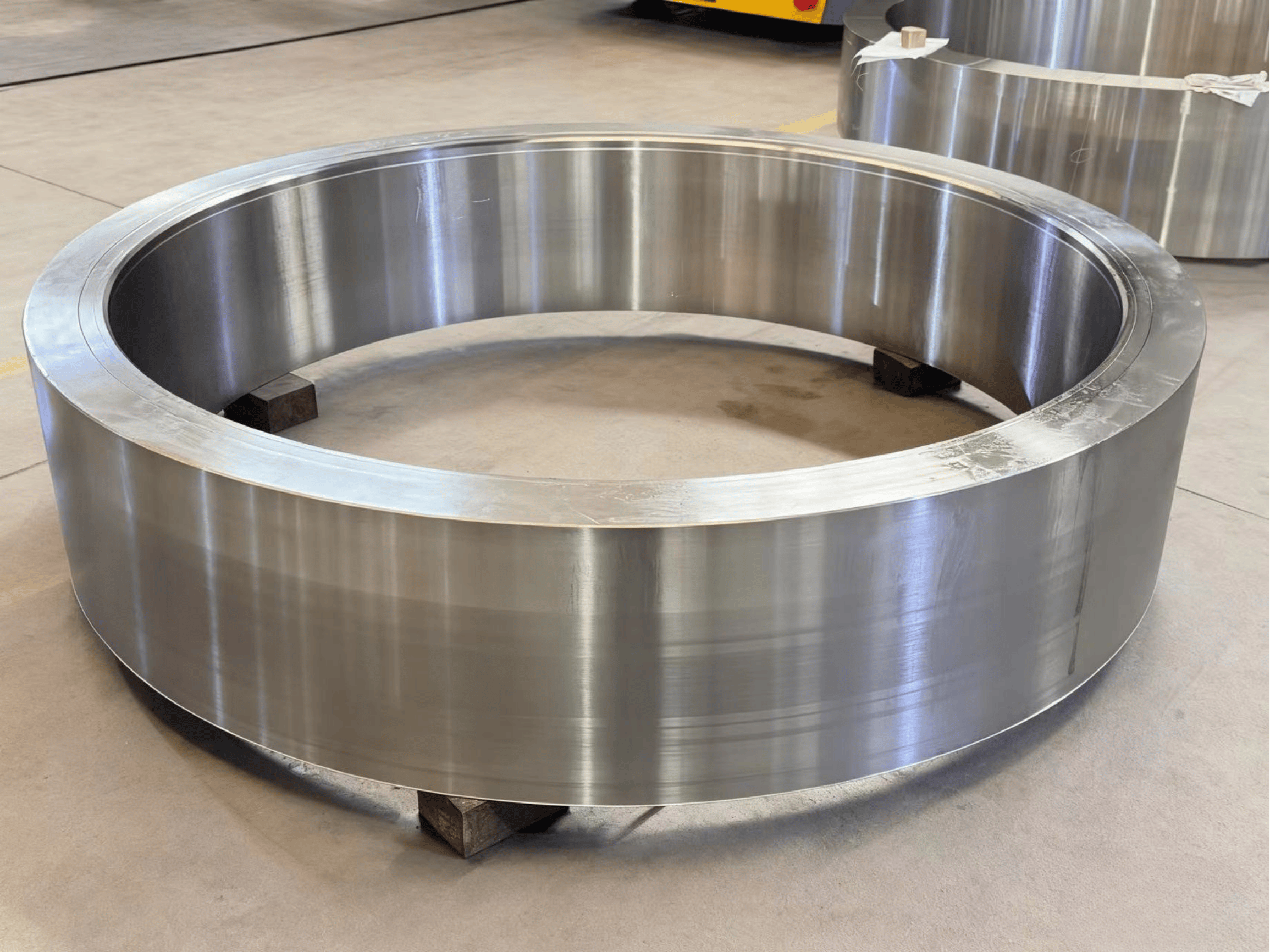

Large-diameter Seamless Ring rolling represents a key benchmark in the global forging industry. Operating within the ≤5-meter diameter range enables optimal convergence of material stability, production efficiency, and metallurgical control.

At this scale, Ring Rolling is no longer simple plastic deformation—it becomes a controlled engineering discipline. By optimizing steel composition, thermal cycles, and forming parameters, each forged ring, Gear Blank, bearing ring, or shaft component achieves reliable mechanical performance under high torque and extreme operating conditions.

Maintaining consistent deformation temperature is critical to preventing internal stress concentration. Uniform thermal control directly influences the microstructure of alloy steels such as 42CrMo4 and 18CrNiMo7-6, ensuring toughness, fatigue resistance, and structural reliability.

Rapid expansion of large rings requires precise prediction and control of wall-taper distribution. This is essential for producing high-precision gear blanks and Bearing Rings with uniform thickness and dimensional accuracy suitable for downstream machined components processing.

Large rings are susceptible to “egg-shaped” deformation when force distribution is uneven. Real-time corrective rolling-force coordination ensures roundness control and dimensional consistency.

Customized cooling and normalizing cycles reduce residual stress, improve dimensional stability, and prepare rings for precision machining while preserving metallurgical integrity.

Material properties—including toughness, fatigue strength, and grain-flow alignment—remain highly stable within this diameter boundary, delivering consistent performance for critical transmission applications.

Optimized process control minimizes scrap rates and reduces manufacturing costs, supporting efficient production of medium- and large-scale industrial components.

Reliable machining allowances ensure precise production of wind turbine gearbox gear blanks, industrial bearing rings, and other large-diameter components requiring secondary finishing.

Ring rolling capabilities within this range are tailored for industries demanding high-performance forged products, including wind turbine gearboxes, Heavy Machinery, industrial pumps and compressors, energy equipment, and transmission systems.

Some customers ask whether gear cutting and finish machining are also provided. The strategic decision is to focus exclusively on forging, Heat Treatment, and rough machining.

This approach guarantees metallurgical performance, flexible machining allowances, and seamless compatibility with downstream gear-cutting operations. As a result, forged rings and related semi-finished components are well suited for gearbox and transmission manufacturers.

Technical authority is achieved not by expanding into every process, but by mastering the critical ones with precision. By concentrating on seamless ring rolling up to 5 meters in diameter, manufacturing operations can deliver:

Operating within this defined boundary ensures process consistency, balanced cost-performance, and high forging quality for demanding industrial applications.

Email to this supplier

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.