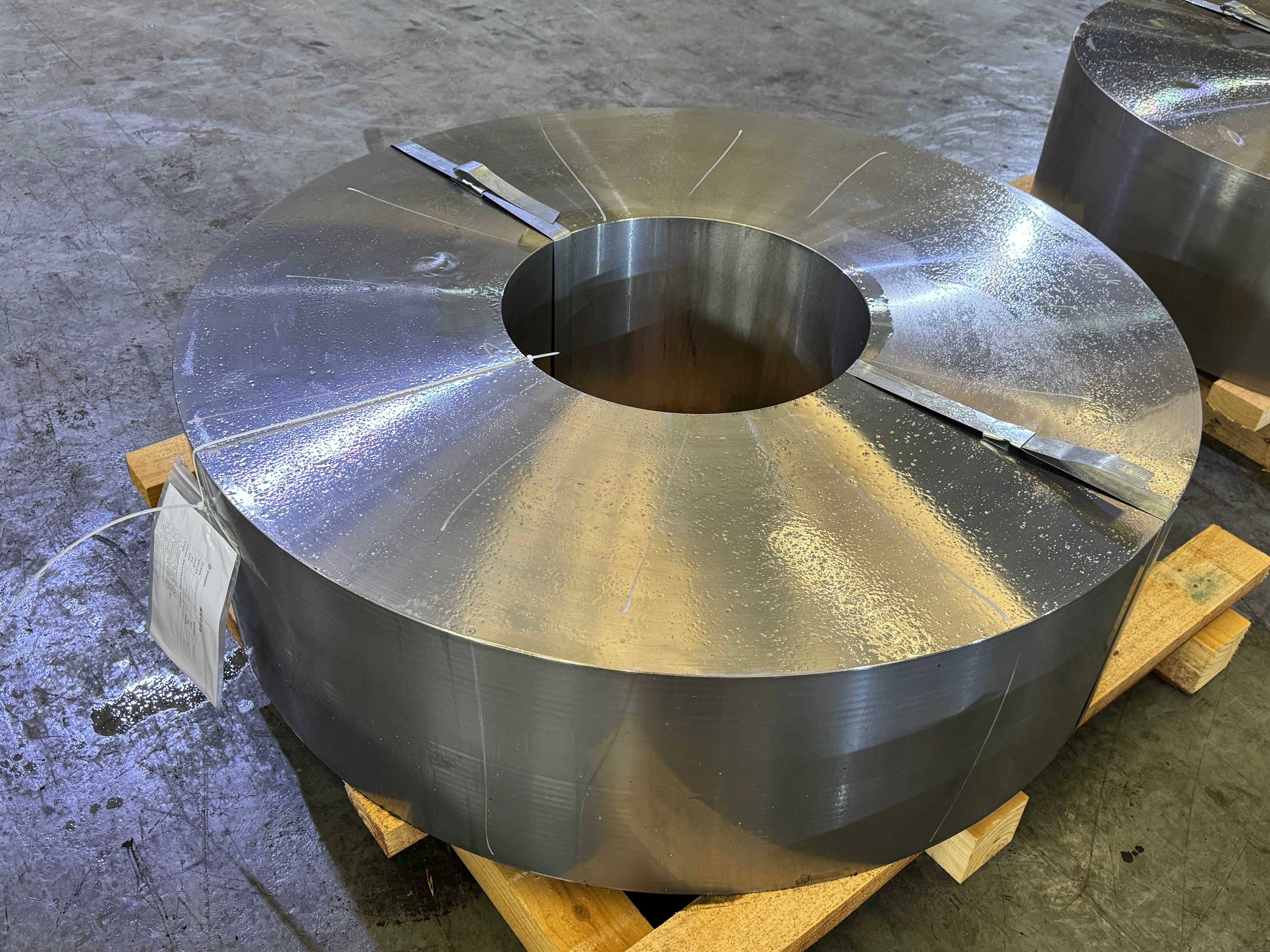

The sun gear serves as the "heart" of the planetary drive system in a wind turbine gearbox. As the central driving gear, it is engineered for efficient and reliable transmission of extreme torque. Our wind turbine gearbox sun gear blanks are manufactured from premium Alloy Steel (e.g., 18CrNiMo7-6) through

Precision Forging and machining, delivering exceptional bending fatigue strength and contact fatigue strength.

We specialize in producing large sun gear blanks covering a size range up to ≤5 meters in diameter and 100 kg to 9 metric tons in weight. Whether you require a first-stage sun gear for low-speed, high-torque applications, or a second-stage sun gear for high-speed transmission, we can supply high-quality

Forged Blanks after preliminary heat treatment. All products are manufactured to the most stringent quality standards. By integrating optimized heat treatment processes (such as normalizing + tempering, quenching and tempering) and comprehensive inspection (Ultrasonic Testing, Spectroscopic Analysis), we ensure every sun gear meets the demands of heavy-duty, long-life operation—both internally and externally.

Manufacturing Process & Quality Assurance 1. Incoming Material Inspection

2. Blank Cutting

3. Ring Rolling

4. Post-Forging Visual & Dimensional Inspection

5. Heat Treatment: Quenching & Tempering / Normalizing + Tempering

6. Mechanical, Chemical & Metallurgical Testing

7. Machining of NDT Surfaces

8. UT & NDT Inspection

9. Rough Turning

10. Ultrasonic Testing, Spectroscopic Analysis, Hardness Measurement

11. Semi-Finish Turning

12. Dimensional Accuracy Inspection

13. Final Hardness Testing

14. Marking, Cleaning & Packaging

Material: Utilizes high-grade alloy steels like 18CrNiMo7-6 to ensure core mechanical properties.

You might also be interested in our flagship products:

Explore our complete product range and contact us for tailored solutions to meet your specific operational requirements.