Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Min. Order:1

Transportation:Ocean,Land

Packaging:Crate

The large storage tank bottom support ring is a critical load-bearing component for pressure vessels and heavy-duty equipment in the petrochemical industry. Designed exclusively to bear the self-weight of equipment, it does not come into contact...

Min. Order:1

Transportation:Ocean,Land

Packaging:Crate

The pressure vessel nozzle is a critical connecting component for petrochemical pressure vessels, designed to facilitate medium transmission between equipment. Engineered with a combination of ring rolling processes, followed by precision CNC...

Min. Order:1

Ring Rolled Bearing Gear Blank forging for Industrial Equipment The Forged Industrial Gear Blank is a high-strength structural forging designed as a foundation component for industrial gear and bearing assemblies. Supplied as a precision-forged...

Min. Order:1

Transportation:Ocean

Packaging:Crate

Ring Rolled Forging Wheel | 42CrMo Alloy Steel Forged Wheel for Industrial Gearboxes Our forging wheels are manufactured using the ring rolling forging process, ensuring exceptional material density, structural integrity, and long-term reliability....

Min. Order:1

Transportation:Ocean

Packaging:Crate

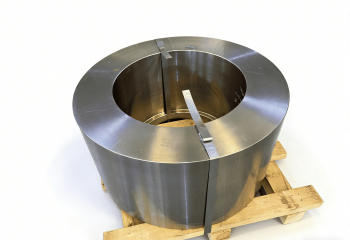

Forged Bearing Cage with Single-Sided Profiling | A Proven Solution Balancing Economy and Reliability Our single-sided profiled forged bearing cage is designed to optimize both material utilization and structural performance. By pre-forming the...

Min. Order:1

Transportation:Ocean

Packaging:Crate

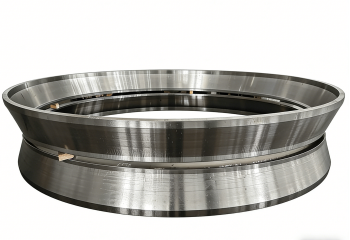

Steel Bearing Cage | Empowering Reliable Operation of Heavy-Duty Equipment A steel bearing cage, also known as a bearing retainer or bearing isolator, is a critical component in rolling bearings. Its primary function is to accurately separate and...

Min. Order:1

Transportation:Ocean,Land

Packaging:Crate

Semi-Finished Forged Ring Gear Blank for Wind Turbine Gearboxes Process Integration, Quality Upgrade Our semi-finished ring gear blank for wind turbine gearboxes represents a significant advancement in manufacturing integration. By bringing the...

Min. Order:1

Transportation:Ocean,Land

Packaging:Crate

Third-Stage Ring Gear: Engineered for High-Speed Power Transmission Operating at the system's final output stage with extreme rotational velocities, this third-stage ring gear blank forms the fundamental basis for ultimate power delivery stability....

Min. Order:1

Transportation:Ocean,Land

Packaging:Crate

Second-Stage Ring Gear: The Robust Core for Torque Multiplication Our Second Stage Forged Ring Gear Blank (Rough Machined) are specifically engineered for the intermediate section of transmission systems, capable of withstanding significantly...

Min. Order:1

Transportation:Ocean,Land

Packaging:Crate

First-Stage Ring Gear: The Ultra-High-Torque Foundation for Heavy-Duty Drivetrains As the largest ring gear in a wind turbine gearbox, the first-stage ring gear is responsible for bearing the initial high-torque input from the main shaft....

Min. Order:1

Transportation:Ocean,Land

Packaging:Crate

Ring Gear: The Critical Power Transmission Link Our ring gears represent the pinnacle of precision machining, designed as the essential outer ring within planetary drive systems. Manufactured from high-strength alloy steel and subjected to rigorous...

Min. Order:1

Transportation:Ocean

Packaging:Crate

Double-Sided Profiled Bearing Cage | Near-Net Shaping Technology for High-End Applications The double-sided profiling process is a high-precision forging technology developed based on our in-house capability to design and manufacture ring-rolling...

Ring Rolling forms metal rings by continuously rolling heated blanks in a circular direction. Ring rolling forms seamless metal rings by continuously rolling heated blanks in a circular direction. This technique aligns the metal grains along the ring, improving strength, toughness, and fatigue resistance. It is commonly used for Bearing Rings, gear rings, planetary gears, sun gears, shrink discs, and forging wheels. Depending on the application, these rolled blanks can undergo Heat Treatment—such as normalizing, quenching, tempering, or annealing—to optimize mechanical performance and ensure long service life.

After rolling, the blanks can be further processed in-house through rough or precision machining, providing a solid foundation for high-performance components and a seamless transition to our Machined Rings category, where precision-finished counterparts are delivered for demanding industrial and heavy-duty applications.

Partner with Liaoyuan to secure large diameter Forgings that provide strength, durability, and traceable quality.

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.